Weighfeeders

Tailored solutions for precise material handling

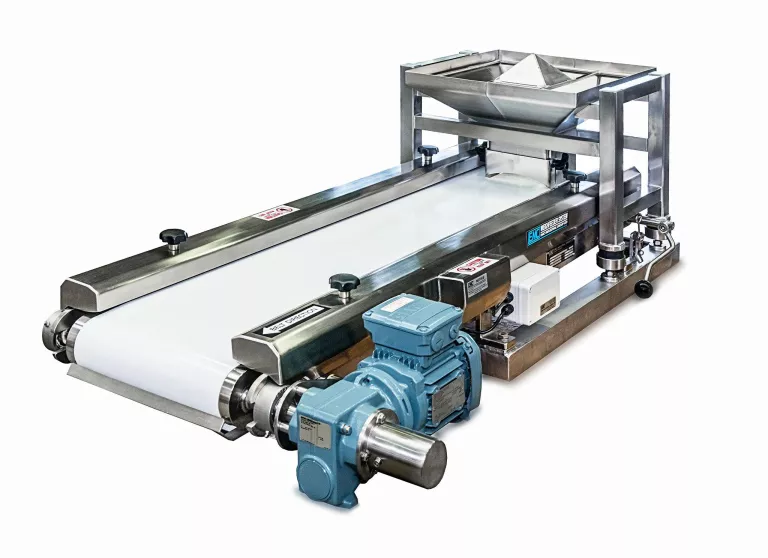

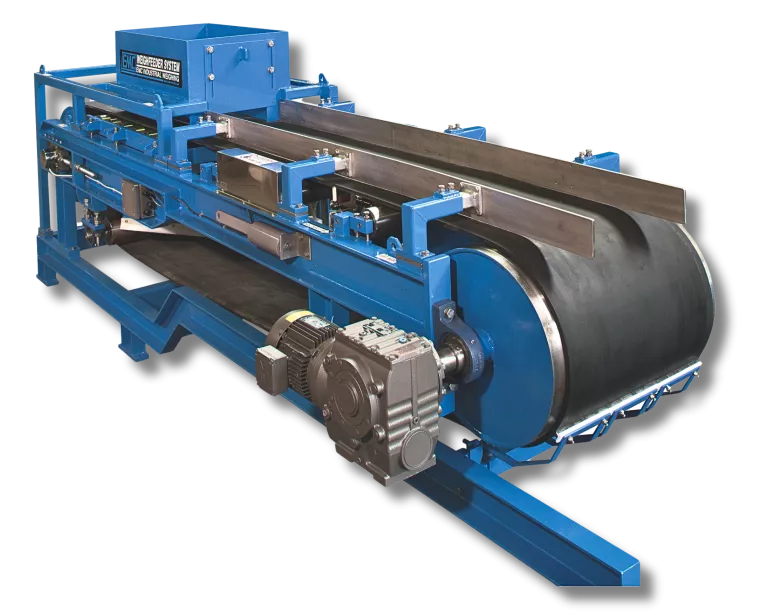

EMC Weighing Weighfeeder Systems offer a straightforward and accurate method for measuring and controlling the flow rate of bulk materials passing over a belt. These systems transport and weigh bulk material from a hopper on a driven belt, with the weight on the weigh section measured by a high-resolution load cell. Our ModWeigh processor calculates the flow rate based on the weight and measured belt speed, ensuring precise control by varying the belt speed as needed.

Key components of our standard systems are:

- Three-idler weigh section with integrated load cell

- Direct drive sealed Gearmotor

- Belt speed measured via tail drum encoder

- ModWeigh MW96A Processor for flow rate calculation and control

Proven experience

Since manufacturing our first weighfeeder in 1973, we have supplied hundreds of units throughout New Zealand and worldwide. This extensive practical experience ensures our systems feature robust mechanical design and construction proven in various industries and applications. Our ModWeigh Series of weighing processors, renowned internationally for quality and ease of operation, has been a cornerstone of our success for over 40 years.

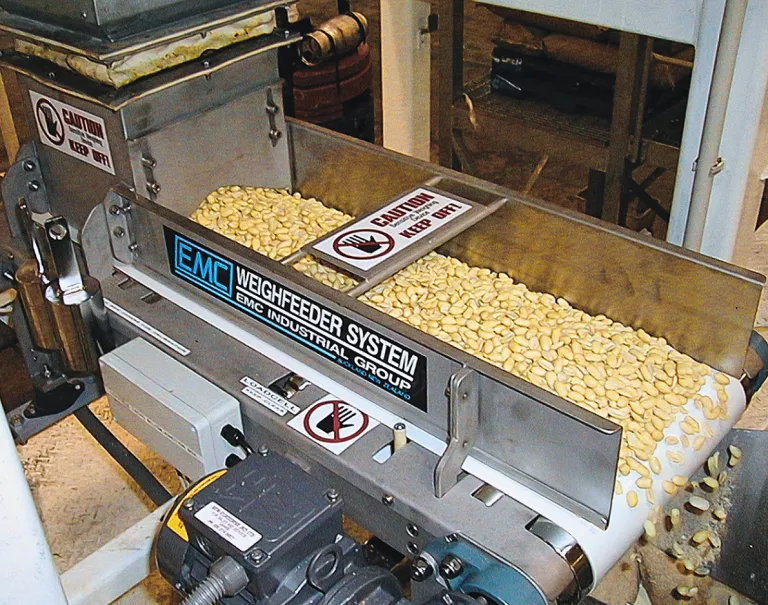

Weighfeeder applications

Weighfeeders have applications across diverse industries including mining, quarrying, cement, fertiliser, chemical, steel, timber, and food processing. These systems play a crucial role in optimising production and blending processes, accurately measuring a wide range of products such as fertilisers, coal, sand, iron sand, aggregates, wood fibre/chips, wool, cereals, vegetables, tobacco, powder, and more.

Weighfeeder functions

- Maintaining bulk material flow rates to optimise efficiency and product quality in processes like kilns, dryers, and grinding mills

- Continuous blending of materials to achieve desired recipes

- Measurement of production rates

- Batching materials where bin weighing is not practical

EMC Weighing design

Our standard weighfeeders are meticulously engineered units crafted to maintain or monitor flow rates with an exceptional accuracy of better than 0.5%.

The weigh section features three precision-machined idler rollers, with the weigh roller mounted on a flexure suspension system, ensuring the accurate transfer of belt weight to a high-resolution load cell. To prevent accidental overloads, the load cell is fully protected by precision stops.

Drive is provided by a sealed gearmotor, ensuring direct and efficient operation without the mess of chains or belts. Belt speed is accurately measured from the tail drum encoder, preventing belt slip and minimising flow rate errors.

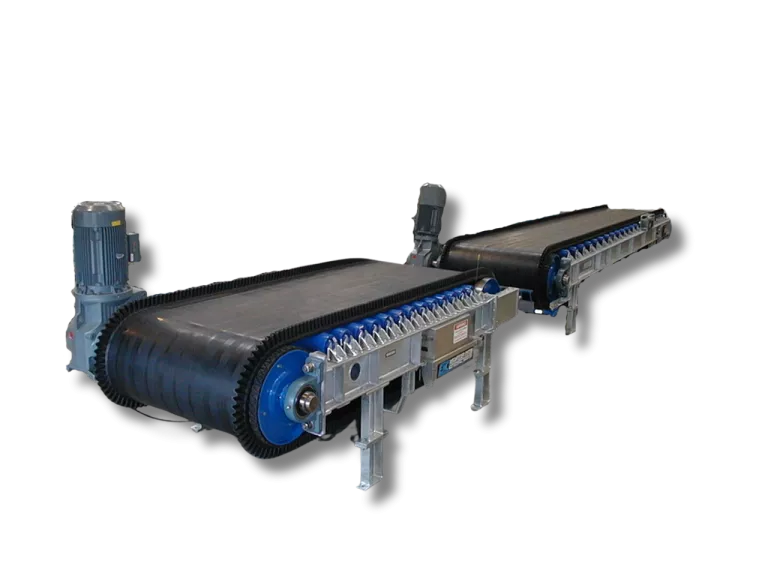

For weighfeeders ≤600mm width, belt steering is managed by crowning of the drive and tail drums. On larger models, belt steering is facilitated by a pneumatic actuator.

In most cases, both rollers and drums are hard chrome plated, while bearings are of the sealed-for-life type. Standard features include side guards (if required), inner and outer belt scrapers, a junction box, and calibration weights.

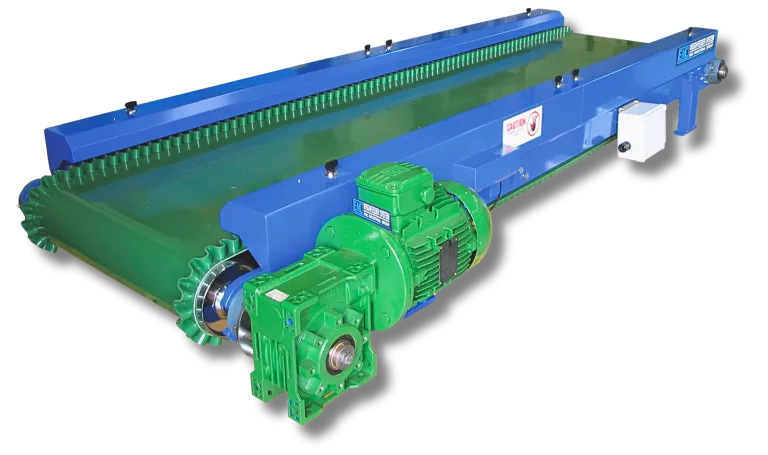

Rugged industrial construction

Built to withstand harsh and aggressive industrial environments, our weighfeeders are constructed with durability in mind. We offer a variety of construction options to suit different conditions.

Standard models are constructed from steel, acid-etched before being electrostatically powder coated for added protection. Additionally, options include galvanised and stainless steel construction. For applications requiring dust control, fully enclosed versions are available, along with hermetically sealed stainless steel load cells.

Standard weighfeeder models

Our standard range of weighfeeders are available in four sizes, ranging from 400mm to 1200mm belt width, with nominal maximum flow rates from 7 to 110 t/hr.

While our standard models fulfil a wide variety of applications, we understand that customisation may be necessary to meet specific requirements. Therefore, if our standard models do not perfectly suit your needs, we offer custom-built systems tailored to your specifications.

Choose EMC Weighing for tailored weighfeeder solutions designed to meet your specific requirements, backed by decades of expertise and comprehensive local support throughout New Zealand and worldwide.

Browse our Resource Library for more information on weighfeeders including brochures, manuals and technical information.

Proven expertise, global reach

With a legacy dating back to 1973, we've delivered thousands of reliable weighing systems and solutions across New Zealand and worldwide. Our extensive hands-on experience ensures that every system we create is built for durability, precision and the unique needs of diverse industries.