Process Weighing

Precision weighing for seamless process control

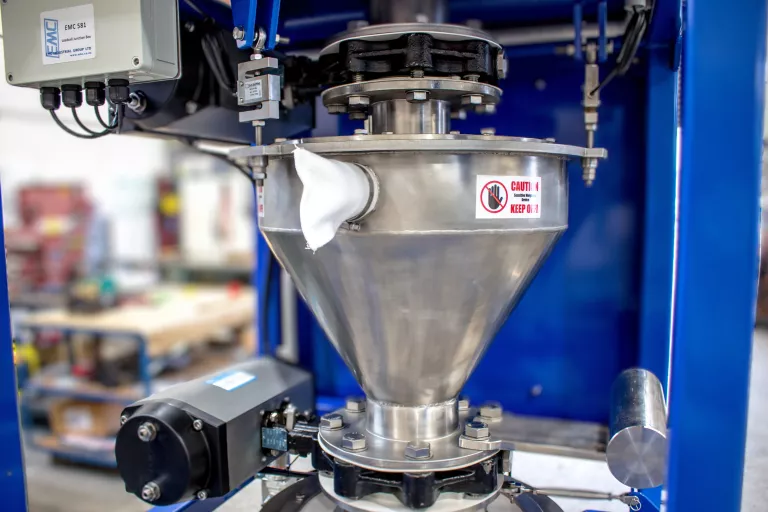

Our process weighers are hygienic, reliable and accurate, designed for precise, continuous weighing in industries such as grain, flour, cement, chemicals, plastics and more.

Our process weighers enable continuous in-process weighing, accurately totalising product as it moves through the system to maintain precise stock records. The analogue output option allows for accurate blending, ensuring consistency in your final product. Additionally, the weigher can be configured to control material flow rates, optimising efficiency in your process.

Key Applications

- Totalising & Stock Records – Accurately track product movement within your process

- Blending & Mixing – Ensures precise blending with an analogue output option

- Bulk Outloading & Batching – Precise control for receiving and dispatching products via silos, road, rail, and more

Features & Benefits

- Hygienic, fully enclosed design for clean operation

- Automatic residue clean-out prevents product build-up

- Simple calibration for easy setup and operation

- Low maintenance for minimal downtime

- Real-time material totalising and flow rate control

Available Options

- Automatic calibration weights

- Two-position catch gate

- Stainless steel contact parts or full stainless steel construction

- Various feeder options: Screw feeder, belt feeder, vibratory feeder

- Radial catch gate, feed bin, discharge chute, and support structures

Our process weighers provide exceptional accuracy, reliability, and flexibility to streamline your material handling and production processes.

Browse our Resource Library for more information on process weighing including brochures, manuals and technical information.

Proven expertise, global reach

With a legacy dating back to 1973, we've delivered thousands of reliable weighing systems and solutions across New Zealand and worldwide. Our extensive hands-on experience ensures that every system we create is built for durability, precision and the unique needs of diverse industries.