Loadstools

Precision for the hide curing industry

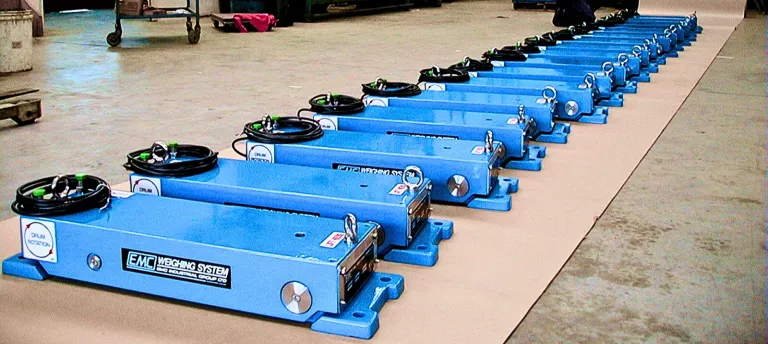

EMC Weighing loadstools are durable, high-precision weighing solutions specifically designed for hide curing drums. Accurate weight measurement ensures consistent, repeatable results in the hide and skin processing industry.

Recognising the need for a reliable solution, EMC Weighing collaborated with tannery engineers to develop its range of loadstools, with the first installation dating back to 1978. Since then, hundreds of units have been manufactured and are successfully operating in tanneries worldwide.

How it works

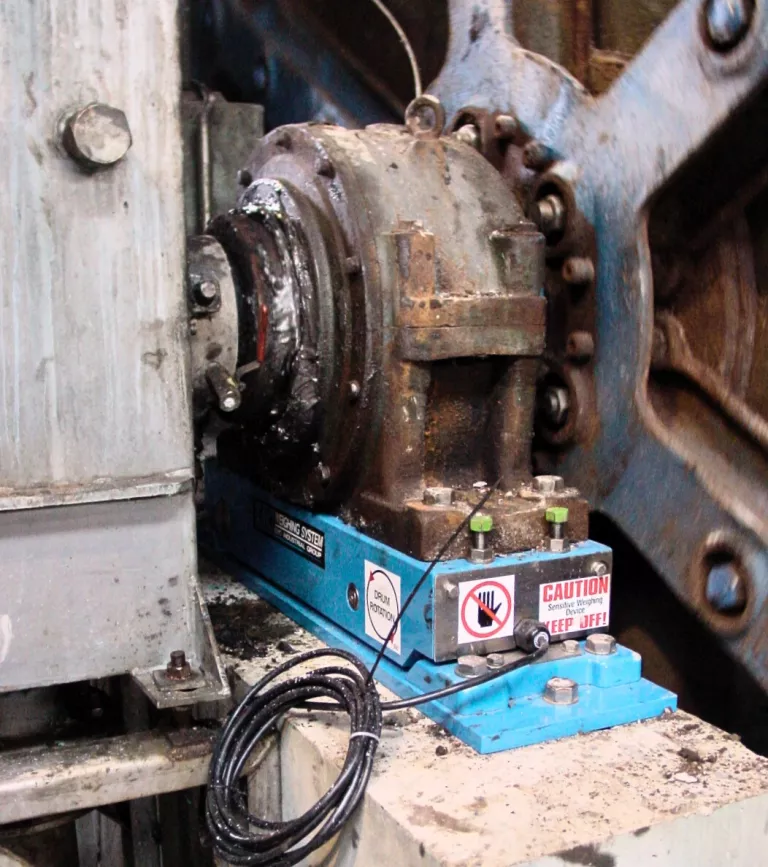

The EMC loadstool is a double flexure-type scale base, utilising eight stainless steel flexures to transfer weight to a single hermetically sealed stainless steel load cell. Heavy-duty stainless steel tie rods secure the weighing section and counteract the out-of-balance forces generated by the rotating drum.

Designed to support the bearing at the non-drive end of the drum, the loadstool can be calibrated using the provided Loadstool Calibration Factor or by filling the drum with a precisely measured amount of water via an accurate flow meter.

Each loadstool comes with an advanced EMC Weighing weight indicator, featuring a microprocessor-controlled digital display and a 4-20 mA output for seamless integration with batching control systems.

Manufacturing, testing and quality assurance

EMC loadstools are built from heavy-section steel plate, sandblasted, and coated with a durable epoxy paint system for long-lasting protection in harsh tannery environments. Stainless steel fastenings further enhance corrosion resistance.

Each unit undergoes rigorous quality control testing in a purpose-built test rig, including:

- 150% overload test to ensure durability

- Preliminary calibration for accuracy

- 10-point linearity test for precision

- Torque testing of all flexure bolts

A signed quality check sheet is included in every customer manual, ensuring transparency and accountability in our ISO 9001 certified manufacturing process.

Compatibility and installation

Our loadstools are designed for use with roller bearings. To prevent damage, the bearings at the drive end of the drum must act as lengthwise restraints. Plain bearings should not be used, as they do not restrain the drum’s movement, leading to longitudinal forces that could compromise the loadstool’s integrity over time.

For decades, EMC Weighing loadstools have set the industry standard for reliable and accurate drum weighing solutions. Contact us today to learn more about how they can optimise your tannery operations.

Browse our Resource Library for more information on loadstools including brochures, manuals and technical information.

Proven expertise, global reach

With a legacy dating back to 1973, we've delivered thousands of reliable weighing systems and solutions across New Zealand and worldwide. Our extensive hands-on experience ensures that every system we create is built for durability, precision and the unique needs of diverse industries.