Belt Weighers

Robust design, reliable performance

EMC Weighing Belt Weigher Systems, also known as Belt Scales, offer a straightforward and precise method for measuring the flow rate and total tonnage of bulk materials transported along a conveyor belt.

Our comprehensive system includes:

- Single, Dual, or Multi-Idler Belt Weigher, featuring integrated load cells for accurate load measurement

- Tacho Assembly to measure belt speed

- ModWeigh MW95A Processor for calculating flow rate (t/hr), totals, and more

Whether your industry is mining, quarrying, cement, fertiliser, chemical, steel, timber, or food processing, belt weighers play a crucial role in production and inventory monitoring.

We also manufacture belt weighers approved for trade use.

Common uses of belt weighers:

- Bulk material measurement

- Bulk inventory control

- Production rate measurement

- Production totals

- Continuous blending systems

- Flow control and blending

Our belt weighers accurately measure a diverse range of products, including fertilisers, coal, sand, iron sand, aggregates, wood fibre, wood chips, vegetables, tobacco, detergent powder, and more.

Rugged industrial construction

The frame of our weighing systems is meticulously crafted for ruggedness, ensuring durability to withstand years of heavy-duty industrial use. Designed for direct mounting to existing conveyor stringers, our frames are versatile and compatible with various setups.

We offer a range of materials and finishes to suit diverse environments, including powder-coated steel, galvanised steel, or stainless steel options. This flexibility ensures our systems can thrive in any setting, from harsh manufacturing floors to sensitive food processing environments.

Our load cells are equipped with full overload protection, safeguarded by precision stops and travel screws. This ensures the integrity of the system during transportation and operation, providing peace of mind in even the most demanding conditions.

Tacho assembly

As standard, a complete tacho assembly with rotary encoder, swivel arm and trailing wheel is provided with each Belt Weigher to measure the belt speed. This bolts to the belt weigher frame and runs on the return belt. As an alternative, we can also offer a tail drum tacho.

Installation, commissioning and service

We can arrange installation and commissioning of your new Belt Weigher System to ensure optimumperformance. Our Service Engineers regularly travel throughout New Zealand and can provide servicereports, maintenance checks and calibration on all our Weighing Equipment.

Our Belt Weigher range

B150 Single Idler Belt Weigher

The B150 Belt Weigher from EMC Weighing is a single idler type unit engineered for simplicity, durability, and hassle-free installation, directly mounting to existing stringers.

Featuring a low-profile design, the complete unit ensures no interference with the returning belt underneath, guaranteeing seamless operation.

The B150 offers exceptional accuracy for a single idler belt weigher, typically ranging between 1-2%.

Constructed with the same materials and finish as the B152 model, the B150 promises years of rugged use. Modified idlers are supported directly on one load cell, ensuring outstanding weighing accuracy from a simple, reliable device.

Features

- Direct or Flexure loading

- Low profile

- Compact, Rugged design

- Custom made to suit each application

- Adjustable idler height

- Adjustable idler roller angle

- Calibration Weight hangers

- Galvanised, powder coated and Two Pot Epoxy finishes available

- Belt Widths up to 900mm

- Designed and Built in New Zealand

Benefits

- Suitable for flat & troughed conveyors

- Accuracies of 1-2% achievable

- Simple to fit

- Adjusters allow exact fitting and alignment for best accuracy

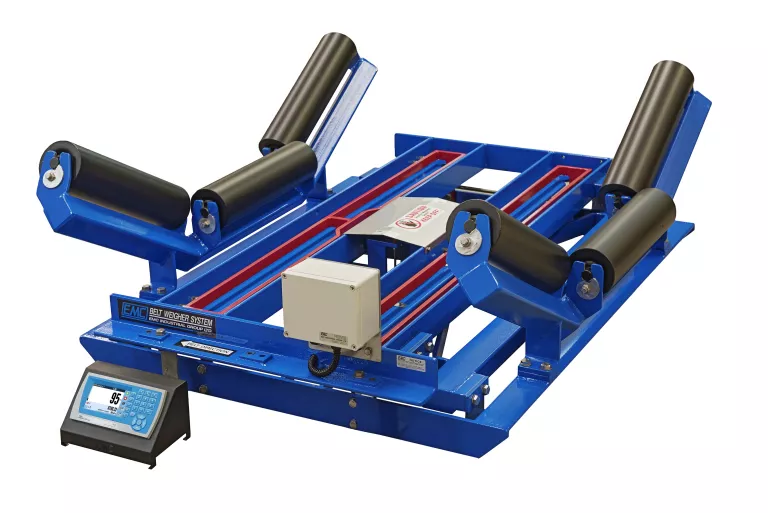

B152 Dual Idler Belt Weigher

Our B152 dual idler belt eeighers are engineered to deliver unparalleled accuracy, typically achieving 0.5% accuracy or better. These systems feature two idler sets mounted on a precision flexure weigh frame, ensuring precise and reliable measurements.

The weigh frame incorporates multiple stainless steel flexures, which efficiently transfer the load from the idlers to a centrally mounted waterproof load cell. With a total movement of the lever arms and load cell measuring less than 0.05mm, the system boasts virtually no moving parts, enhancing its durability and reliability.

Thanks to the scale section's construction, counterweights can be utilised to offset the deadweight of the idlers and belt. This innovative design enables the reliable weighing of products with low bulk density, ensuring accurate measurements in diverse applications.

Features

- Flexure based loading system

- Compact, Rugged design

- Custom made to suit each application

- Counterbalancing of deadload for increased accuracy

- Adjustable idler height

- Adjustable idler roller angle

- Calibration Weight frame

- Galvanised, powder coated and Two Pot Epoxy finishes available

- Belt Widths up to 1,800mm

- Designed and built in New Zealand

Benefits

- Approved for trade use in New Zealand

- Suitable for flat & troughed conveyors

- Suitable for low loaded applications such as wood chips

- Accuracies of 0.5% achievable

- Simple to fit

- Adjusters allow exact fitting and alignment for best accuracy

B162 Dual Idler Belt Weigher

Our B162 dual idler Belt Weighers are engineered for exceptional accuracy, with typical performance of 0.5% or better. Featuring a precision fully suspended weigh frame and direct force measurement, these systems ensure reliable and accurate readings without the need for lever arms, pivots, or bearings.

Features

- Precision fully suspended weigh frame

- Direct force measurement (no lever arms, pivots or bearings)

- 2 or 4 load cells

- 2 idler weigh platform

- Individually engineered/custom designed

- Designed for minimal material build up

- Mild steel construction or stainless steel for extreme environments

- Galvanised, powder coated and Two Pot Epoxy finishes available

- Designed and built in New Zealand

Benefits

- Suitable for flat & troughed conveyors

- Accuracies of 0.5% achievable

- Simple to install

- Adjusters allow exact fitting and alignment for best accuracy

- Optional ‘on board’ calibration weights for easy calibration

B154 Multi-Idler Belt Weigher

We are also able to design and manufacture multi-idler belt weighers specifically for your needs and application.

For example, our B154 four idler belt weighers are engineered to deliver unparalleled accuracy, typically achieving 0.25% accuracy or better. This system features four idler sets mounted on a precision flexure weigh frame, ensuring precise and reliable measurements.

Features

- Precision fully suspended weigh frame

- Direct force measurement (no lever arms, pivots or bearings)

- Multiple load cells

- Multi idler weigh platform

- Individually engineered/custom designed

- Designed for minimal material build up

- Mild steel construction or stainless steel for extreme environments

- Galvanised, powder coated and Two Pot Epoxy finishes available

- Designed and Built in New Zealand

Benefits

- Suitable for flat & troughed conveyors

- Suitable for low loaded applications such as wood chips

- Accuracies of 0.25% achievable

- Simple to install

- Adjusters allow exact fitting and alignment for best accuracy

Browse our Resource Library for more information on belt weighers including brochures, manuals and technical information.

Proven expertise, global reach

With a legacy dating back to 1973, we've delivered thousands of reliable weighing systems and solutions across New Zealand and worldwide. Our extensive hands-on experience ensures that every system we create is built for durability, precision and the unique needs of diverse industries.